PRE-PRODUCTION:

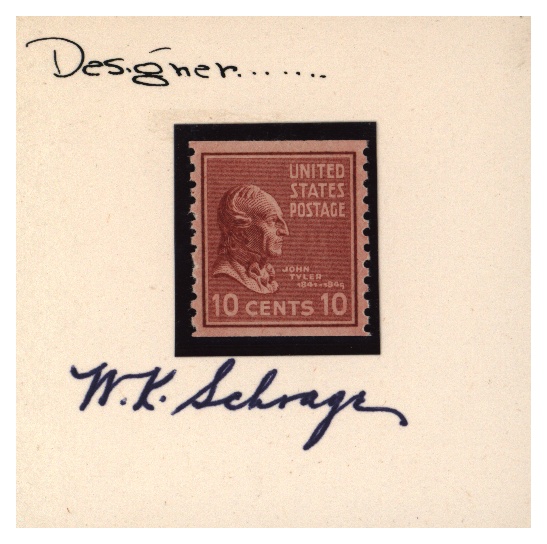

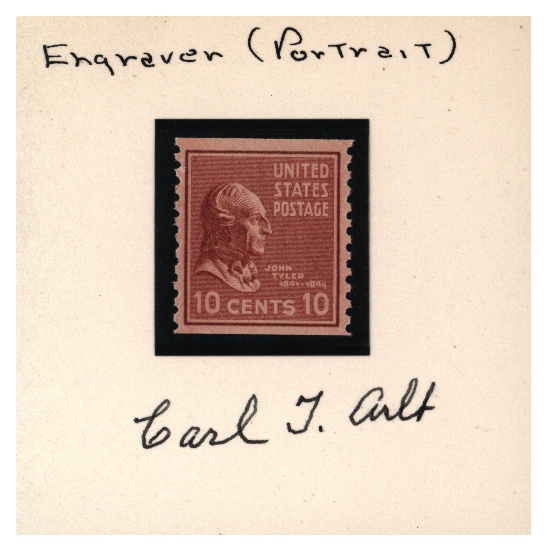

Large die proof of the 10c value.

Only one known.

Once the die was approved, the plates would be prepared.

As the stamps entered the production process, they would first be printed then perforated, counted, split into strips and rewound.

ROTARY PRESS:

All coils of the Presidential Series were printed on the Stickney Rotary Press

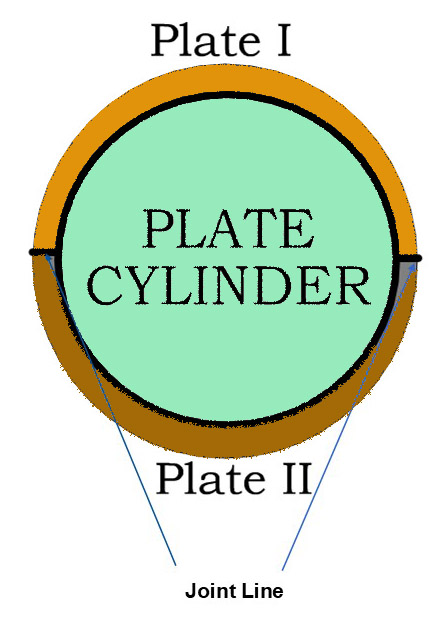

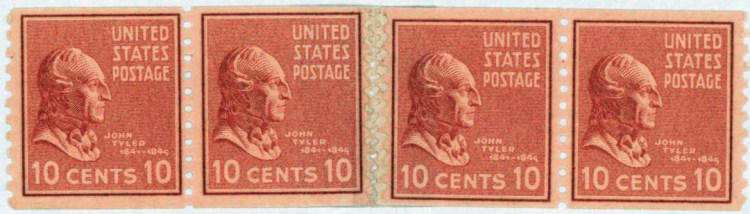

Two plates wrapped around the cylindrical bed of the rotary press. (See figure at right.) This created a joint line every 17 stamps on the sidewise coils. Depending upon the position of the plates on the cylinder, there would be some variation in the joint line.

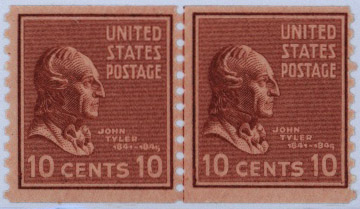

The thickness of the line depended upon how well the plate fit together.

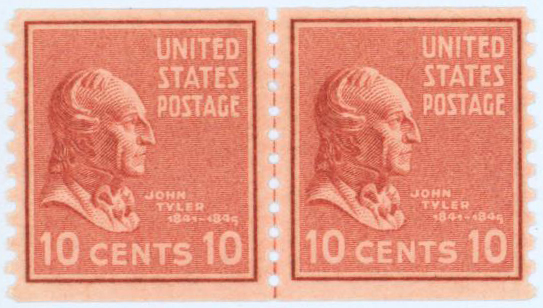

Misalignment of the plates was caused by misplaced gripper slots or a slight shift when clamping the plate to the cylinder. Note right stamp is higher than the left.

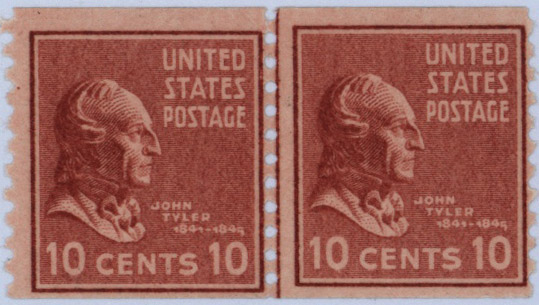

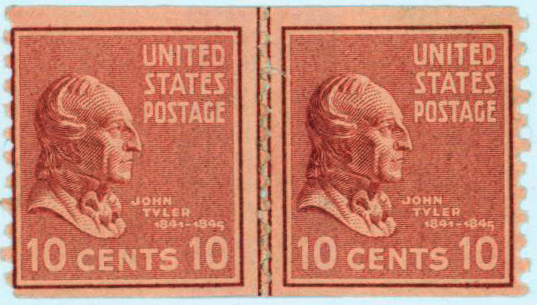

Differences in the curvature of the plates caused the plates to meet at an uneven heights., creating a blush of color on one side of the joint line.

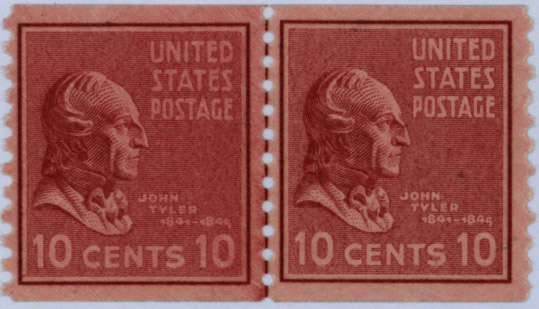

The standard height of the Fifth Bureau Coils is 25mm. This includes the engraved areas and the margins. The example below are “jumbos,” a full millimeter higher.

PERFORATIONS:

After printing, stamps were sent to the perforating machine. In spite of the long period of use and large printing quantities, few perforation errors are known for the coils, none for the 10c value. There are some minor varieties.

While no imperforate varieties are known, examples known as blind perforations can be found. Blind perforations show the imprint of the pins, but they have not punched all the way through.

Broken perforation pins cause small imperforate areas. The most likely cause for such examples was war time shortages and delayed non-essential maintenance. Here the sixth pin is missing.

There has been discussion that large and small hole varieties exist as in the Liberty Series. While there are variations in the hole sisize, it has to do with the speed of the web or sharpness of the pins, creating holes of different sizes. They are not a separate variety.

PLATE NUMBERS:

The sidewise coils were printed on plate with 10 horizontal rows of 17 stamps. The only plate markings were two plate numbers. One is preceded by a star. Miscuts could expose the plate number, which was normally trimmed away.

Both these miscuts are from plate 22101. The top strip of 5 comes from the bottom of the plate. The left three stamps, ending with the number are from plate 22101. The two stamps on the right are from the companion plate on the rotary drum. The reverse is true for the bottom strip.

PASTE UPS:

To repair web breaks or join the ends of two webs, splices were made with perforated, gummed paper. Repairs were usually made at the line, with stamps between the two lines discarded. This was for easy counting. For this reason, pastes ups are more likely found with one or two lines showing. Paste ups without a visible line are unusual.

Back of pair to left showing perforated tape.

LEADER STRIPS:

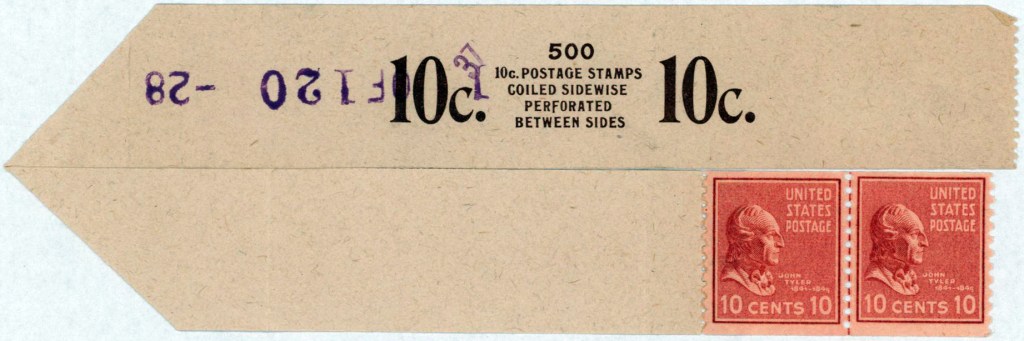

Web printing involved a continuous roll of paper. Those printed in coil format were run across a measuring table to be broken into size. Paper tape was added at the beginning and end of the roll.

Examples above show both leader and trailer strips from roll of 500. Kraft paper was used until the 1950s when paper was changed to white.

COLOR:

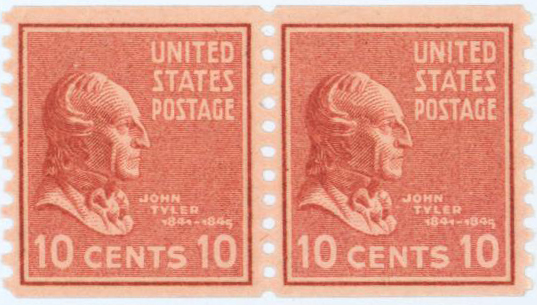

The hue of the 10c value runs from red-orage brown to dark orange-brown. The ink of this value is more susceptible to color alteration and can be found in shades of yellow and pink.

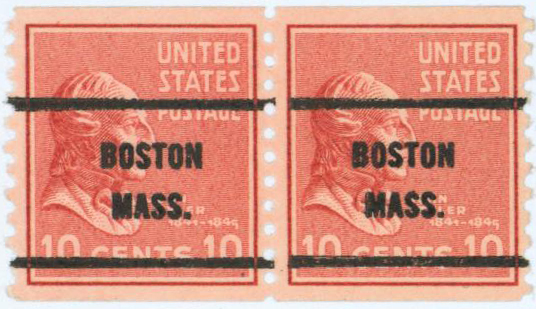

PRECANCELS:

Only four cities are known with Bureau precancels of the 10c coil. Stamps were precanceled as part of the printing process on the rotary press. The four cities are illustrated below.